Unveiling the Power of Fiber Optic Cable Jetting Machines On-Site

- July 20, 2023

- Posted by: cable blowing machine

- Categories: Cable Jet, Fiber cable blowing machine

In the dynamic world of telecommunication infrastructure, fiber optic cable jetting machines technology stands tall as the backbone of high-speed data transmission. To ensure seamless connectivity, contractors and technicians must employ cutting-edge equipment. Among these innovations, fiber optic cable jetting machines have emerged as a game-changer in revolutionizing on-site installations. This article explores the remarkable working mechanism of these machines, highlighting their prowess in boosting efficiency and meeting the demands of today’s fast-paced telecom industry.

-

Understanding Fiber Optic Cable Jetting Machines

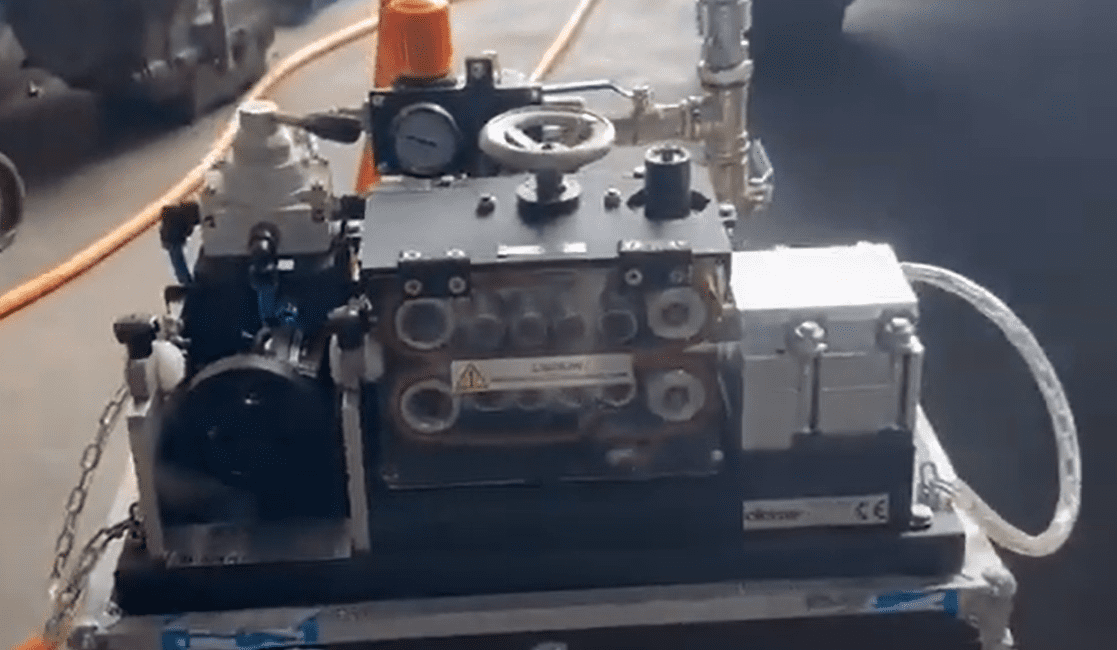

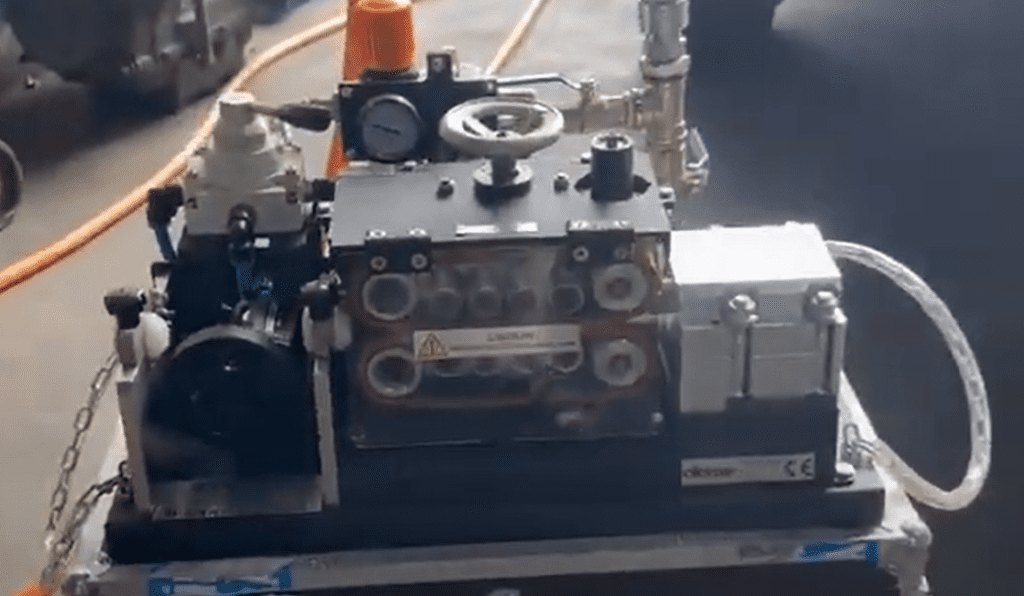

Fiber optic cable jetting machines, also known as fiber blowing machines, are ingenious devices designed to facilitate the installation of fiber optic cables into ducts. These machines are a critical asset, particularly for FTTH (Fiber to the Home) and FTTx (Fiber to the X) deployments. The process involves blowing the fiber optic cables through microducts or pipes, ensuring precise and secure placement.

- Key Factors for Seamless Cable Installation

a. Cable Diameter and Pipe Diameter: The compatibility between the cable diameter and the pipe diameter is paramount. Fiber optic cable jetting machines can handle a wide range of cable and pipe sizes, offering flexibility during installations.

b. Air Pressure and Duct Installation: The success of the cable blowing process depends on maintaining optimal air pressure. By regulating air pressure, contractors can efficiently navigate bends and corners, minimizing cable damage and ensuring smooth installation.

c. Blowing Speed and Distance: These machines offer adjustable blowing speeds, accommodating various installation scenarios. Contractors can control the blowing distance, allowing for precise placement in underground ducts, even over extended distances.

d. Compressor Power: The compressor provides the necessary air pressure to propel the cables into the ducts. A robust compressor ensures continuous and consistent blowing performance.

-

Unleashing the Benefits

a. Enhanced Efficiency: Fiber optic cable jetting machines significantly reduce installation time compared to traditional methods. They streamline the process by automating cable placement, minimizing manual labor, and potential human errors.

b. Cost-Effectiveness: Faster installations lead to cost savings for both contractors and clients. Reduced labor hours translate into increased project turnover, enabling businesses to take on more projects and expand their reach.

c. Minimal Disruptions: Cable jetting machines work swiftly, causing minimal disruptions to existing infrastructure during installations. This is particularly vital for urban settings, where minimizing downtime is crucial.

d. Superior Cable Protection: With controlled air pressure, the risk of cable damage due to excessive force is eliminated, ensuring the longevity and performance of the fiber optic cables.

Fiber optic cable jetting machines have revolutionized the telecom industry by simplifying and accelerating cable installations. With their ability to handle various cable and pipe diameters, along with adjustable blowing speeds and distances, these machines provide unmatched efficiency and precision. For contractors and businesses seeking to optimize their FTTH, FTTx, and underground installations, investing in fiber optic cable jetting machines is a strategic choice that promises long-term benefits and customer satisfaction. Embrace this technology, and stay ahead in the ever-evolving world of telecommunication infrastructure.