Fiber optic cable blowing machines have become an essential tool for telecommunication contractors and companies looking to install fiber optic cables underground quickly and efficiently. These machines use compressed air to push fiber optic cables through microducts installed in underground pipes, allowing for faster installation and fewer disruptions to the environment.

However, understanding the installation process for fiber optic cable blowing machines can be overwhelming for those who are new to the technology. In this article, we will break down the installation process into simple steps and explain the different components involved.

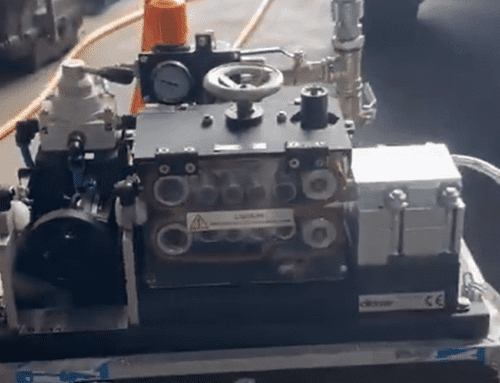

Cable blowing jetting machine

Step 1: Pre-Installation Planning

Before any installation can begin, there needs to be a proper plan in place. This plan should consider the location, terrain, and distance of the fiber optic cable to be installed, as well as the cable diameter, pipe diameter, and air pressure needed for the installation.

Step 2: Microduct Installation

Once the pre-installation planning is complete, the microducts need to be installed in the pipes. Microducts are small tubes made of plastic that are designed to house the fiber optic cables. The microducts are typically installed in a straight line to create a clear path for the cables.

Step 3: Fiber Optic Cable Preparation

Before the fiber optic cables can be blown through the microducts, they need to be prepared for installation. The cables are typically attached to a cable jet or a cable jetting machine, which is used to create an airtight seal between the cable and the microduct.

Step 4: Blowing the Fiber Optic Cable

Once the fiber optic cable is prepared, it can be blown through the microducts using a fiber optic cable blowing machine. The machine uses compressed air to create a high-pressure stream of air, which pushes the cable through the microducts. The blowing speed and distance depend on the cable diameter, pipe diameter, and air pressure.

Step 5: Testing and Inspection

After the fiber optic cable has been blown through the microducts, it needs to be tested and inspected to ensure that the installation was successful. This includes testing the cable for any damages or defects, as well as ensuring that the cable is in the correct location and position.

FAQs:

- What is a fiber optic cable blowing machine? A fiber optic cable blowing machine is a device used to install fiber optic cables underground quickly and efficiently.

- How does a fiber optic cable blowing machine work? The machine uses compressed air to create a high-pressure stream of air, which pushes the fiber optic cable through microducts installed in underground pipes.

- What is a microduct? A microduct is a small tube made of plastic that is used to house fiber optic cables during installation.

- What is the purpose of a cable jetting machine? A cable jetting machine is used to create an airtight seal between the fiber optic cable and the microduct during installation.

- What factors affect the blowing speed and distance of a fiber optic cable? The cable diameter, pipe diameter, and air pressure all affect the blowing speed and distance of a fiber optic cable.

- How is the fiber optic cable tested after installation? The cable is tested for any damages or defects, as well as ensuring that the cable is in the correct location and position.

- What are the benefits of using a fiber optic cable blowing machine? Using a fiber optic cable blowing machine allows for faster installation and fewer disruptions to the environment compared to traditional installation methods.

- What are some common challenges faced during fiber optic cable installation? Common challenges include the location, terrain, and distance of the fiber optic cable, as well as the availability of suitable underground pipes for installation.

[…] Pneumatic fiber floating machines, also known as fiber optic cable blowing machines, play a crucial role in the installation of fiber optic cables. These machines use compressed air to create a high-pressure stream of air that helps push the fiber optic cable through conduits or microducts. Understanding the functions of pneumatic fiber floating machines is essential for telecommunication contractors and companies involved in fiber optic cable installations. […]